How does it work...

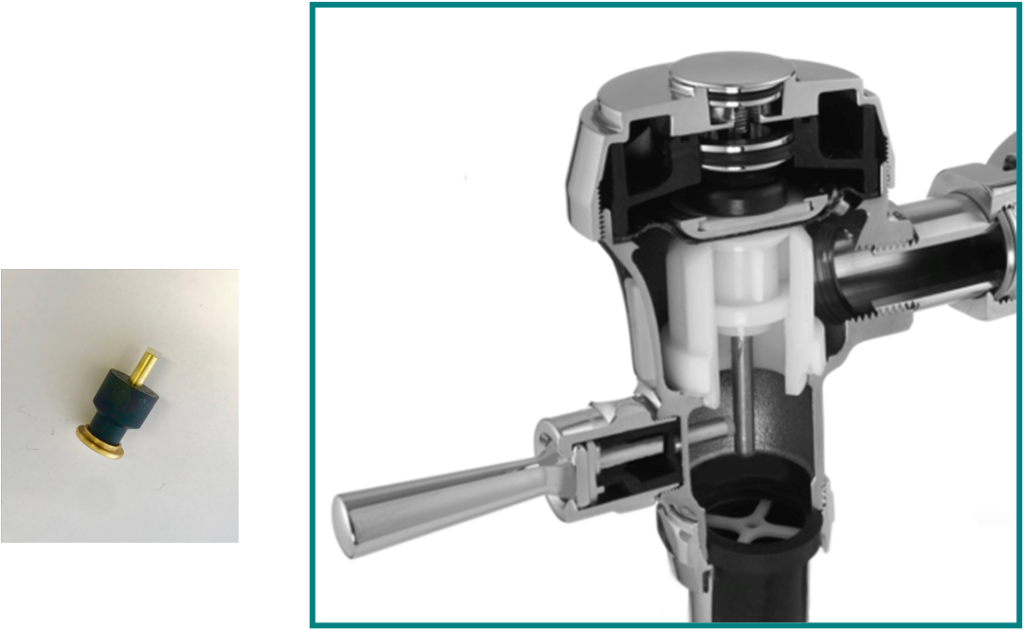

The Regulation Screw was introduced in 1948. It was a patented feature at that time. It works by allowing the you to change the timing of the flush valve. The discharge for a flush is determined by two (2) factors. The first and most important is size of the bypass orifice. The smaller the hole the more slowly the upper chamber will refill and thus shut the diaphragm (or piston) down. A large hole such is used for today’s HEU pint urinal allows the upper chamber to refill very quickly, which shuts flush off quickly and you get just small amount of water. In this case of the 0.125 gpf urinal, you get just a pint of water. There is second factor though and that is how far the diaphragm or piston travels. This is relationship is set by the factory before a valve is shipped and the other companies all fix this relationship. Delany and only Delany allows the maintenance team in the field to adjust this relationship and or the timing by changing the height of the Regulation Screw. It is accessed through the cover by removing the small cap cover and a screwdriver slot is found inside. The user can then either raise or lower the screw. Raising the screw will allow the diaphragm/piston to go higher and thus take longer to travel back down, resulting in a little more water being added to the discharge. If one lowers the screw, then less water will be generated during the flush cycle. The ability to fine tune a flush when needed ulimately results in water savings verses only being allowed to make major changes to the discharge that waste water. This is the heart of the True-in-the-Field Water Conservation concept.

How does it work...

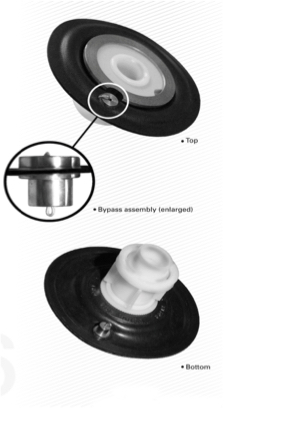

Introduced in 1999, the Mashaerator is monel wire that passes through the bypass with a loop. As the diaphragm rises and falls during the flush cycle, the Mashaerator’s loop design will turn deflecting larger debris away from the bypass. The Mashaerator also has the freedom to move up and down. This motion allows the smaller particles that may have gotten into the bypass to pass through. Keeping the bypass open is the key to preventing a flush valve from “”running”” or continous flush.

The Rubberflexer

The Rubberflexer, introduced and patented back in 1956, provides a leak-free seal from a chloramine resistant rubber that is also ADA Compliant. Testimonials from facilities team experts attest to the fact that the Rubberflexer inside every Delany handle indeed never leaks. Additionally, the Rubberflex Handle allows for easy to maintain and is a fraction of the cost to repair compared to the other competitor’s handles.

How does it work...

The Rubberflex Handle assembly is the industry’s only NON-spring loaded handle assembly. Instead the Delany handle uses the Rubberflexer, allowing water to enter through the handle pad, making the rubberflexer expand and seal on the inside of the of the handle pad. The EPDM rubber may break down over time, but no matter how times it is kicked it will not leak. This a claim only Delany can make.

The Removeable Main Valve Seat

For the building owner, Delany’s Removeable Seat offers them the most cost-effective solution in cases of wire draw or scoring, and for the contractor, it allows them for the fastest and most thorough means of flushing of the water supply lines at the job’s completion, saving time and money by having less call backs.

How does it work...

Delany’s Removeable Seat is made of delrin plastic and is threaded into place. This then allows the owner/facilities team to uise a 12-point socket wrench to remove and replace it if and when it becomes damaged. Competitor’s valves have permenant cast main valve seats and if wire draw occurs, the only recourse is to replace the entire valve, not a simple part. Even better for contractors, the ability to remove the seat means there is nothing obstructing the water flow during the flushing process. This allows the contractor to know with confidence that the supply lines are 100% clean. A permenant main valve seats prevent the water from flowing freely and debris gets caught by them, which later can get into a diaphragm bypass and cause the flush valve to run. Call backs are a contractor’s biggest nightmare.