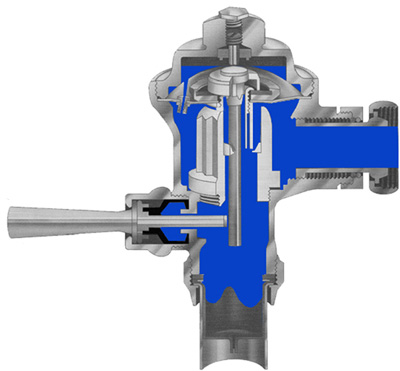

Valve Operation

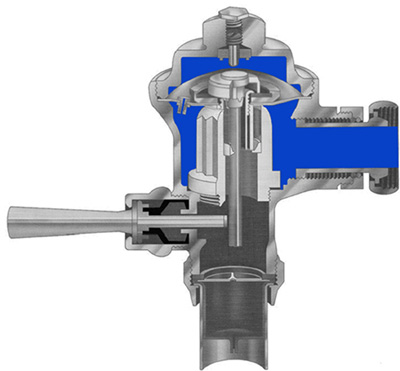

Valve at rest

The upper chamber and lower chamber are both filled with water at supply line pressure.

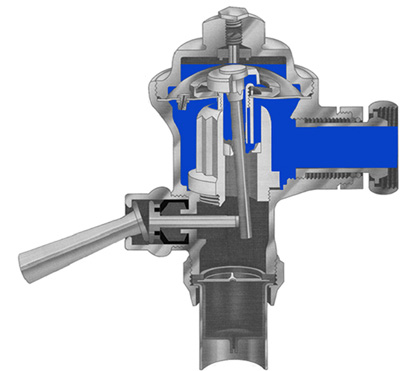

Start of flush

As the handle is depressed, the operating stem pushes against the stem of the auxiliary valve, tilting the head of the auxiliary valve on its seat. Immediately, a quantity of water is released from the upper chamber into the outlet of the flush valve. Since the pressure in the upper chamber is reduced, the pressure in the lower chamber forces the diaphragm upward.

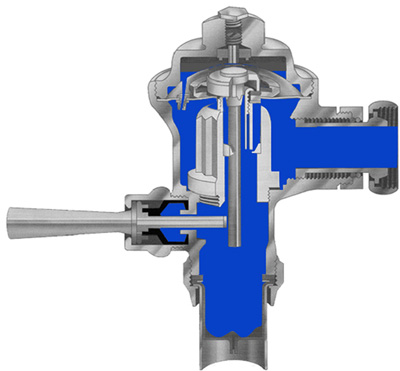

Valve fully opened

The diaphragm rises upward until its stroke is halted by the contact with the regulating screw in the valve cover. The auxiliary valve is reseated on the auxiliary valve seat. Syphonic action of fixture takes place at this point.

Valve closing

Flushing action continues until enough water enters the upper chamber through the bypass orifice in the diaphragm to refill the upper chamber and equalize the pressure with that of the lower chamber.

The area subject to pressure on the upper side of the diaphragm is greater than the area subjected to pressure on the lower side. Hence, once the pressure has been equalized, the diaphragm begins to slowly descend to the main valve seat, closing off the flow of water and completing the cycle.